123 Model Potato Flour Processing Machine Peeling Washing Cutting Grinding Drying Pack 380V

Product Details:

| Place of Origin: | henan china |

| Brand Name: | ZY |

| Certification: | CE |

| Model Number: | PR |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | negotiable |

| Packaging Details: | wooden box |

| Delivery Time: | 30-45days |

| Payment Terms: | TT |

| Supply Ability: | 25set/month |

|

Detail Information |

|||

| Function: | Peeling, Washing, Cutting, Grinding, Drying, Packing | Warranty: | 1 Year |

|---|---|---|---|

| Voltage: | 380V50hz | Model: | PR500 |

| After-Sales Service Provided: | Engineers Available To Service Machinery Overseas | Material: | Stainless Steel 304 |

| Application: | Potato Flour Production | ||

| Highlight: | 380V Potato Flour Processing Machine,Peeling Potato Flour Processing Machine,Washing Potato Flour Processing Machine |

||

Product Description

Product Description:

The Potato Flour Processing Machinery is an integrated solution designed specifically for the production of high-quality potato flour. This machinery line is a combination of various machines, each serving a critical function in the transformation of raw potatoes into a fine, ready-to-use flour. The processing machinery encompasses the entire production line, starting from the initial preparation of the potatoes to the final packaging of the potato flour.

The first stage in the potato flour production process involves the use of a Potato washing machine. This machine is designed to efficiently clean the raw potatoes, ensuring that all dirt, soil, and other impurities are removed before proceeding to the next step. Our washing machine is robust and features advanced technology to maintain the integrity of the potatoes while thoroughly cleansing them.

After the potatoes are cleaned, they undergo peeling to remove their skin, which is not desired in the flour production. The peeling process is facilitated by state-of-the-art machinery that minimizes waste and maximizes productivity. Following the peeling, the potatoes are then sent to be cut into smaller pieces. This cutting process is important as it prepares the potatoes for a uniform grinding process, ensuring consistency in the potato flour produced.

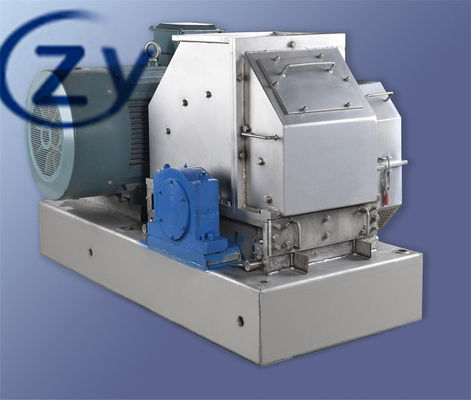

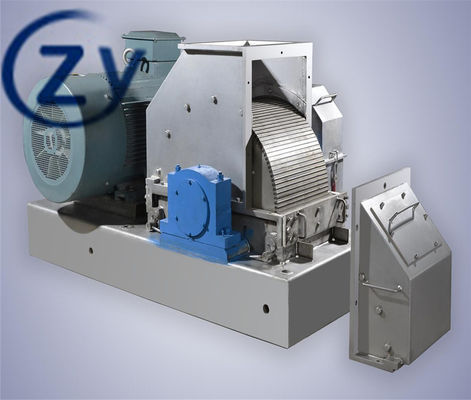

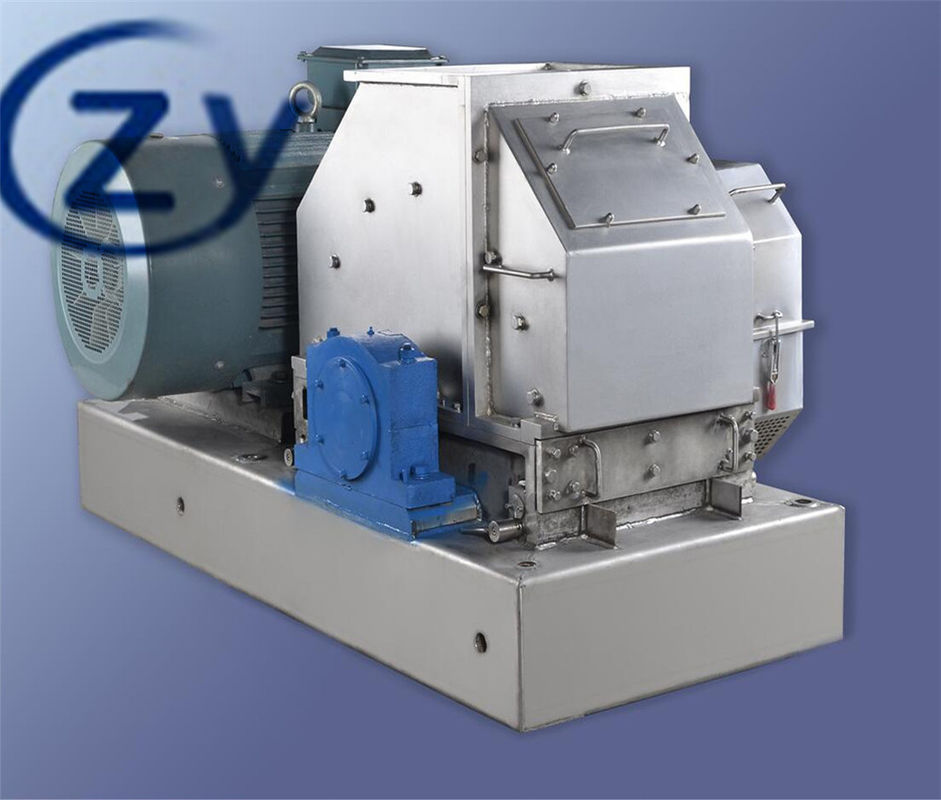

The Potato crushing machine is a pivotal component of the processing line. Its function is to grind the cut potato pieces into a mash. The machinery is engineered to handle the robust requirements of crushing and is capable of producing a smooth and homogeneous potato paste, which is essential for high-quality flour.

One of the key features of this processing line is the inclusion of a Paddle washer. After the potatoes are crushed, the paddle washer effectively removes excess starch and fine particles, further refining the potato paste before it is sent for drying. The paddle washer is designed to be gentle on the potato paste while ensuring thorough cleansing, contributing to the overall quality of the potato flour.

Subsequent to washing and refining, the potato paste must be dried. Our processing machinery includes an advanced drying system that carefully eliminates moisture content from the potato paste without affecting its quality. The drying process is critical to achieving a fine, powdery texture, which is characteristic of premium potato flour. Once drying is completed, the dry flour is sifted to ensure uniformity in texture and quality.

The final step in the potato flour production line is the packing process. The machinery is equipped with a precise packing system that measures and packs the potato flour into various packaging sizes, based on customer requirements. This system ensures that the flour is securely packed, maintaining its freshness and quality during storage and transport.

All components of the Potato Flour Processing Machinery are designed to operate at a voltage of 380V, ensuring compatibility with industrial power supplies and efficient energy consumption. Additionally, this product comes with a 1-year warranty, providing customers with peace of mind and assurance of our commitment to quality and reliability.

Understanding the importance of customer service and support, we offer comprehensive after-sales service. Our team of skilled engineers is available to service machinery overseas, ensuring that any issues can be promptly and effectively resolved. This service extends to the installation, maintenance, and any necessary repairs of the machinery, thereby ensuring minimal downtime and maximum productivity for our clients.

In summary, the Potato Flour Processing Machinery is an exceptional suite of equipment that encompasses all necessary functions from peeling, washing, cutting, grinding, drying, to packing, to produce high-quality potato flour. With the inclusion of state-of-the-art machines such as the Potato washing machine, Potato crushing machine, and Paddle washer, coupled with our commitment to after-sales service and a 1-year warranty, clients can expect a reliable, efficient, and cost-effective solution for their potato flour production needs.

Features:

- Product Name: Potato Flour Processing Machinery

- Voltage: 380V

- Material: Stainless Steel

- Application: Potato Flour Production

- Function: Peeling, Washing, Cutting, Grinding, Drying, Packing

- Key Feature: Paddle Washer for Effective Washing

- Key Feature: Potato Hammer Mill for Fine Grinding

- After-Sales Service Provided: Engineers Available To Service Machinery Overseas

Technical Parameters:

| Material | Stainless Steel |

| Application | Potato Flour Production |

| After-Sales Service Provided | Engineers Available To Service Machinery Overseas |

| Function | Peeling, Washing, Cutting, Grinding, Drying, Packing |

| Model | 123 |

| Warranty | 1 Year |

| Voltage | 380V |

Applications:

The ZY brand, hailing from Henan, China, presents its advanced Potato Flour Processing Machinery, specifically designed for efficient and high-quality potato flour production. As a part of its robust product line, the model PR123 incorporates the latest in food processing technology, meeting the stringent CE certification requirements. This machinery is an essential acquisition for businesses looking to scale up their potato flour production with a minimum order quantity of just one set.

Featuring a powerful Potato Rasper, the ZY PR123 efficiently breaks down potatoes into a fine slurry, a crucial step in achieving a smooth, high-grade potato flour. The precision engineering of this machinery ensures that the texture and quality of the flour produced meet the industry's highest standards. This makes the ZY PR123 model an ideal choice for various application occasions, ranging from large-scale food processing plants to smaller boutique operations that demand a consistently superior product.

At the heart of the cleaning process, the ZY PR123 model includes a Paddle Washer – an essential component that thoroughly washes potatoes, ensuring that any dirt or impurities are removed before processing. This feature is particularly beneficial for scenarios where the raw potatoes come from various sources and may carry different levels of debris. The Paddle Washer guarantees that the potatoes are prepped and pristine, ready for the next stage of processing.

The potato flour processing machinery is not just powerful but also adaptable to various scenarios. Whether it is for a continuous production line or a standalone processing unit, the ZY PR123's voltage requirements of 380V make it suitable for a range of industrial settings. Moreover, the machinery comes with comprehensive packaging details, including a secure wooden box ensuring safe delivery within 30-45 days. The price remains negotiable, reflecting ZY's commitment to providing cost-effective solutions to its clients.

Payment for the machinery is facilitated through TT (Telegraphic Transfer), offering a reliable and traceable method of transaction. The ZY PR123 boasts a supply ability of 25 sets per month, illustrating the brand's capacity to fulfill high-volume orders promptly. Furthermore, after-sales service is a cornerstone of ZY's customer service, with engineers available to service machinery overseas, ensuring that any operational issues can be addressed swiftly and efficiently.

With a warranty of 1 year, purchasers of the ZY PR123 Potato Flour Processing Machinery can operate with the confidence that their investment is protected. This warranty, coupled with the exceptional after-sales service, underscores the reliability and durability of the machinery. It's clear that the ZY PR123 is crafted for a variety of application scenarios, promising to be an indispensable asset for any enterprise focused on the high-quality production of potato flour.

Customization:

Brand Name: ZY

Model Number: PR-123

Place of Origin: Henan, China

Certification: CE

Minimum Order Quantity: 1 set

Price: Negotiable

Packaging Details: Wooden box

Delivery Time: 30-45 days

Payment Terms: TT

Supply Ability: 25 sets/month

Warranty: 1 Year

Application: Potato Flour Production

After-Sales Service Provided: Engineers Available To Service Machinery Overseas

Model: 123

Function: Peeling, Washing, Cutting, Grinding, Drying, Packing

Our ZY brand Potato Flour Processing Machinery, model PR-123, is a comprehensive solution for potato flour production. This machinery, originating from Henan, China, is CE certified and comes with a one-year warranty. The machinery includes a Potato Rasper, also known as a Potato crushing machine, which ensures efficient peeling, washing, cutting, grinding, and drying of potatoes before packing. With a minimum order quantity of just one set and a supply ability of 25 sets per month, our machinery is packaged in a sturdy wooden box ensuring safe delivery within 30-45 days. The price is negotiable, and payment is accepted through TT. Moreover, we offer excellent after-sales service with engineers available to service machinery overseas to keep your production running smoothly.

Support and Services:

Our Potato Flour Processing Machinery comes with comprehensive technical support and services to ensure your equipment operates smoothly and efficiently. Our expert team is dedicated to providing assistance with installation, troubleshooting, operation, and maintenance of your machinery. We offer guidance on optimizing your production line for maximum output and quality.

Our services include detailed manuals and easy-to-follow guides that cover the safe and effective use of our machinery. We also provide online resources such as FAQs, video tutorials, and tips for best practices in potato flour processing.

In the event of technical difficulties, our responsive support team is equipped to help diagnose and resolve issues swiftly. We are committed to minimizing downtime and helping you maintain continuous production. For more complex problems or maintenance, we may offer virtual support sessions or dispatch a technician for on-site assistance, depending on your specific service package.

Regular software updates and hardware maintenance recommendations are part of our ongoing commitment to your success. We also provide information on spare parts and consumables to ensure that your machinery stays in prime condition for years to come.

Our customer service extends beyond initial purchase and setup. We believe in nurturing long-term relationships with our clients by providing continuous support and periodic check-ins to discuss any needs for upgrades or additional training for your staff.

Rest assured that our Potato Flour Processing Machinery is backed by a dedicated team ready to support your operational needs and contribute to your business growth.

Packing and Shipping:

The Potato Flour Processing Machinery is carefully packaged to ensure its protection during transportation. Our packaging process includes several steps to maintain the integrity of the machinery. Initially, each component is wrapped in a protective layer to prevent scratches and damage. Following this, the parts are securely placed in a sturdy wooden crate, specially designed to hold the machinery snugly and prevent movement that could cause harm.

The wooden crate is then sealed and labeled with all the necessary information, including handling instructions, product details, and shipping information. Before dispatch, the crate undergoes a final inspection to guarantee that the packaging meets our high standards for safety and quality.

Regarding shipping, we select reputable carriers with a proven track record for handling industrial equipment. The machinery is shipped with insurance coverage to safeguard against any unforeseen events during transit. Customers will receive a tracking number to monitor the shipment's progress and estimated delivery time.

Upon arrival, we advise customers to inspect the package for any external damage before signing the delivery receipt. In the event of any issues, please contact our customer service immediately to assist with the resolution.

FAQ:

Q1: What is the brand and model number of the potato flour processing machinery?

A1: The brand name of the potato flour processing machinery is ZY, and the model number is PR.

Q2: Where is the ZY Potato Flour Processing Machinery manufactured?

A2: The ZY Potato Flour Processing Machinery is manufactured in Henan, China.

Q3: What certifications does the ZY Potato Flour Processing Machinery have?

A3: The ZY Potato Flour Processing Machinery comes with CE certification.

Q4: What is the minimum order quantity for the ZY Potato Flour Processing Machinery?

A4: The minimum order quantity for the ZY Potato Flour Processing Machinery is 1 set.

Q5: How is the ZY Potato Flour Processing Machinery packaged for delivery?

A5: The ZY Potato Flour Processing Machinery is packaged in a wooden box to ensure its safety during transportation.

Q6: How long does it take to deliver the ZY Potato Flour Processing Machinery after placing an order?

A6: The delivery time for the ZY Potato Flour Processing Machinery is typically 30-45 days after placing an order.

Q7: What are the payment terms for purchasing the ZY Potato Flour Processing Machinery?

A7: The payment terms for purchasing the ZY Potato Flour Processing Machinery are TT (Telegraphic Transfer).

Q8: What is the supply ability of the ZY Potato Flour Processing Machinery?

A8: The supply ability of the ZY Potato Flour Processing Machinery is 25 sets per month.