Multi Function Potato Flour Processing Machine 123 Stainless Steel 380V Voltage Machinery

Product Details:

| Place of Origin: | henan china |

| Brand Name: | ZY |

| Certification: | CE |

| Model Number: | PR |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | negotiable |

| Packaging Details: | wooden box |

| Delivery Time: | 30-45days |

| Payment Terms: | TT |

| Supply Ability: | 25set/month |

|

Detail Information |

|||

| Model: | 123 | Function: | Peeling, Washing, Cutting, Grinding, Drying, Packing |

|---|---|---|---|

| Application: | Potato Flour Production | Warranty: | 1 Year |

| Voltage: | 380V | Material: | Stainless Steel |

| After-Sales Service Provided: | Engineers Available To Service Machinery Overseas | ||

| Highlight: | 380V Potato Flour Processing Machine,Stainless Steel Potato Flour Processing Machine |

||

Product Description

Product Description:

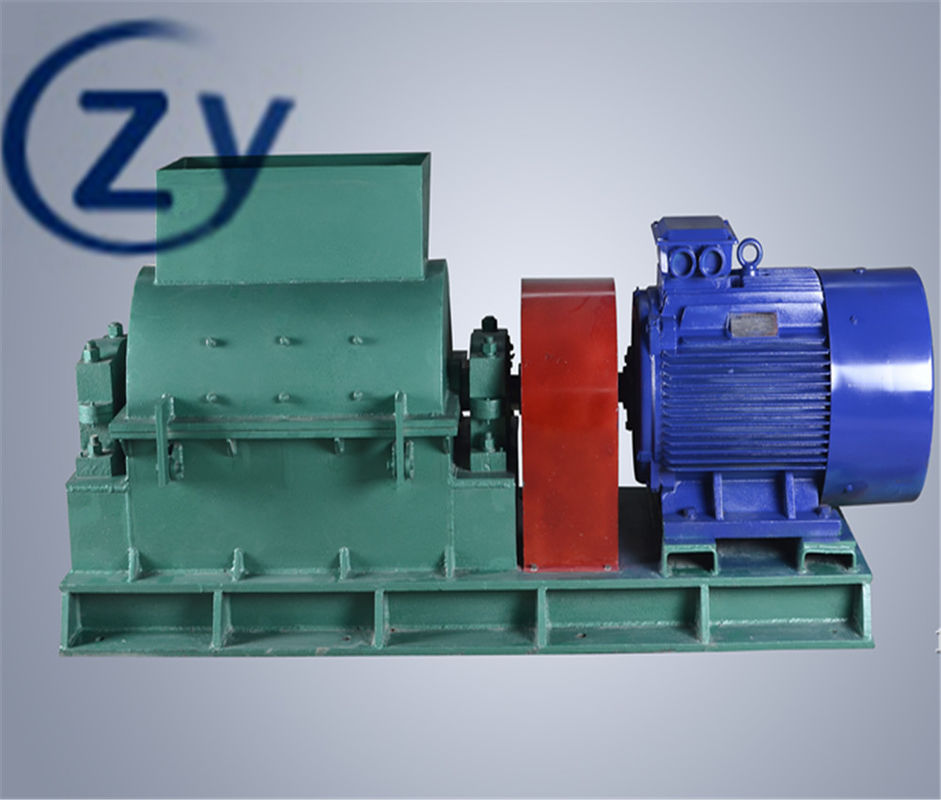

The Potato Flour Processing Machinery, model 123, is an advanced solution for businesses looking to streamline their potato flour production. With a focus on reliability and efficiency, this machinery is designed to transform raw potatoes into fine, high-quality potato flour suitable for a variety of culinary applications. The comprehensive setup includes several key components, each integral to the production process, including a Potato hammer mill, Paddle washer, and Potato crushing machine, among others.

At the core of the processing line is the Potato hammer mill, a robust piece of equipment engineered to pulverize the potatoes into a fine powder. The hammer mill's precision and power ensure that the potatoes are ground down with minimal waste, maximizing productivity and yield. The mill's design facilitates easy maintenance and cleaning, allowing for continuous operation and a consistent output of potato flour.

The Paddle washer is another essential component of the Potato Flour Processing Machinery, model 123. This machine is meticulously crafted to cleanse the raw potatoes thoroughly before they enter the milling phase. Equipped with high-efficiency paddles, the washer agitates the potatoes, removing dirt, stones, and other impurities. This not only enhances the quality of the final product but also protects the hammer mill and other downstream equipment from potential damage caused by foreign objects.

Following the washing stage, the Potato crushing machine takes over to break down the potatoes into smaller pieces. This initial crushing is crucial to ensure uniformity in size before milling, which contributes to the consistency of the flour's texture. The crushing machine is built to be both powerful and gentle, ensuring that the integrity of the potato is preserved, leading to a flour that retains the potato's natural flavor and nutritional benefits.

Model 123 of the Potato Flour Processing Machinery operates on a voltage of 380V, which is standard for industrial equipment, providing the necessary power for large-scale production without compromising on energy efficiency. The machinery's electrical components are carefully selected to ensure safety, reliability, and compliance with international standards.

Understanding the importance of operational continuity for our clients, we offer exceptional after-sales service. Our commitment is to provide engineers who are available to service machinery overseas, ensuring that any issues can be swiftly addressed and downtime is minimized. This service extends to both preventive maintenance and corrective interventions, with a focus on customer satisfaction and the longevity of the machinery.

In addition to our comprehensive after-sales service, the Potato Flour Processing Machinery comes with a 1-year warranty. This warranty covers the repair or replacement of parts that may be defective in materials or workmanship. Our clients can rest assured that they are investing in a product that is supported by a guarantee of quality and reliability.

The application of this machinery is specifically tailored to potato flour production. Its design takes into account the unique properties of potatoes as a raw material, ensuring that each stage of the process—from washing to milling—is optimized for the best possible outcome. Whether for commercial bakeries, food processing plants, or specialty food producers, model 123 of the Potato Flour Processing Machinery is the ideal choice for high-quality potato flour production.

In conclusion, the Potato Flour Processing Machinery, model 123, represents a significant advancement in food processing technology. It combines efficiency, durability, and meticulous design to meet the high standards of the food industry. With key features such as a Potato hammer mill, Paddle washer, and Potato crushing machine, this machinery promises to be an invaluable asset for any operation focused on producing top-tier potato flour.

Features:

- Product Name: Potato Flour Processing Machinery

- After-Sales Service Provided: Engineers Available To Service Machinery Overseas

- Material: Stainless Steel 304

- Application: Potato Flour Production

- Model: HM

- Voltage: 380V

- Potato Crushing Machine: Designed for efficient crushing and milling of potatoes into flour

- Potato Washing Machine: Ensures thorough cleaning of potatoes before processing

- Potato Crushing Machine: Robust construction for sustained industrial use

Technical Parameters:

| Parameter | Specification |

|---|---|

| Model | 123 |

| Function | Peeling, Washing, Cutting, Grinding, Drying, Packing |

| Voltage | 380V |

| Application | Potato Flour Production |

| Warranty | 1 Year |

| After-Sales Service Provided | Engineers Available To Service Machinery Overseas |

| Material | Stainless Steel |

Applications:

The ZY brand, with its Model Number PR potato flour processing machinery, stands as a testament to quality and efficiency in the agro-processing industry. Originating from Henan, China, and boasting a CE certification, this robust equipment is designed to cater to diverse application occasions and scenarios, particularly in the large-scale production of potato flour. A minimum order quantity of one set reflects the manufacturer's confidence in the machinery's performance, ensuring that even smaller scale processors can access this high-caliber equipment.

Priced competitively and open for negotiation, the ZY Model PR machinery is encased in a secure wooden box for delivery, which takes about 30-45 days. The payment terms are flexible, with TT being the preferred method, while the supply ability of 25 sets per month ensures that demand is met consistently. With a voltage specification of 380V and a material construction of stainless steel, this machinery promises durability and compliance with industrial standards.

At the heart of the potato flour production line is the Paddle washer and Rotary drum washer components. These are crucial for the initial stages of processing, where they perform the essential task of thorough cleaning, ensuring that the potatoes are free from dirt and other contaminants. The Paddle washer is particularly adept at dislodging soil and stones, while the Rotary drum washer offers a gentle yet effective washing action that preserves the integrity of the potatoes before they proceed to the grinding and milling stages.

The application scenarios for the ZY Model PR are diverse, encompassing small to large-scale potato flour producers who prioritize both quality and volume. The potato washing machine is a workhorse, capable of handling the rigorous demands of continuous operation, making it suitable for businesses looking to scale up their production. The packaging details, including the use of a wooden box, ensure that the machinery arrives in pristine condition, ready for immediate deployment upon delivery.

The after-sales service provided includes engineers available to service machinery overseas, offering peace of mind to the purchaser that any issues that arise will be promptly addressed. This is complemented by a 1-year warranty, adding an additional layer of assurance in the investment. Whether it's a startup venturing into potato flour production or an established manufacturer looking to upgrade their processing line, the ZY Model PR machinery is equipped to meet the operational needs and challenges of the modern food processing sector.

Customization:

Brand Name: ZY

Model Number: PR

Place of Origin: henan china

Certification: CE

Minimum Order Quantity: 1set

Price: negotiable

Packaging Details: wooden box

Delivery Time: 30-45days

Payment Terms: TT

Supply Ability: 25set/month

Application: Potato Flour Production

Function: Peeling, Washing, Cutting, Grinding, Drying, Packing

After-Sales Service Provided: Engineers Available To Service Machinery Overseas

Voltage: 380V

Warranty: 1 Year

Product Description: The ZY Potato Flour Processing Machinery is designed for efficient and high-quality production of potato flour. It includes advanced features such as a Paddle washer, Potato washing machine, and Potato hammer mill, ensuring a thorough cleaning, milling, and processing of potatoes. The complete line is expertly engineered for peeling, washing, cutting, grinding, drying, and packing, providing a turnkey solution for potato flour production. With a strong after-sales service team ready to assist, ZY offers the support needed to maintain operational efficiency and productivity.

Support and Services:

Our Potato Flour Processing Machinery is designed to offer superior performance and reliability. To ensure that you get the most out of your investment, we provide comprehensive technical support and services for our products. Our support includes troubleshooting assistance, guidance on operation and maintenance, as well as advice on optimizing the machinery for your specific production needs.

If you encounter any issues with your machinery, our technical support team is well-equipped to provide the necessary assistance. Our services include remote diagnostics, where possible, to quickly identify and resolve problems without the need for on-site visits. We also offer regular maintenance check-ups and service reports to keep your machinery running at peak efficiency.

For more extensive support, our team of experienced technicians can provide on-site services, including installation, commissioning, and training for your staff to ensure proper use and care of the equipment. We are committed to helping you maintain a high level of productivity and minimizing downtime.

In addition to our standard support services, we offer customized service agreements tailored to your specific requirements. These agreements can include extended warranties, scheduled maintenance plans, and priority technical support to give you peace of mind and help you manage your operations effectively.

Please note that while our technical support and services are comprehensive, they do not cover issues arising from improper use, unauthorized modifications, or external factors beyond our control. We recommend adhering strictly to the operational guidelines provided with your machinery to ensure optimal performance and longevity.

Packing and Shipping:

The Potato Flour Processing Machinery is meticulously packed to ensure the utmost protection during transport. We use robust, industrial-grade packaging materials to safeguard the machinery against any potential damage that could occur during shipping. The packaging is designed to withstand the rigors of long-distance transport, whether by sea, air, or land.

Each component of the machinery is individually wrapped with shock-absorbing materials and securely placed within the packaging container. We use reinforced corners and cushioning materials to prevent movement and abrasion. The outer packaging is made of high-strength, corrugated material that resists tearing and crushing, providing an additional layer of security.

Before dispatch, all packages are thoroughly inspected to ensure they meet our strict packaging standards. We also include all necessary documentation, such as installation guides, operation manuals, and a list of included parts, ensuring a smooth setup process upon arrival.

Our shipping department coordinates with reputable logistics partners to arrange for timely and efficient delivery of the Potato Flour Processing Machinery to your specified location. We offer tracking options so that you can monitor the progress of your shipment, providing you with peace of mind until your machinery reaches its destination safely and ready for operation.

FAQ:

Q1: What is the brand name and model number of the Potato Flour Processing Machinery?

A1: The brand name of the Potato Flour Processing Machinery is ZY, and the model number is PR.

Q2: Where is the Potato Flour Processing Machinery manufactured?

A2: The Potato Flour Processing Machinery is manufactured in Henan, China.

Q3: What certifications does the ZY PR Potato Flour Processing Machinery have?

A3: The ZY PR Potato Flour Processing Machinery is certified with CE.

Q4: What is the minimum order quantity for the ZY PR Potato Flour Processing Machinery?

A4: The minimum order quantity for the ZY PR Potato Flour Processing Machinery is 1 set.

Q5: How is the ZY PR Potato Flour Processing Machinery packaged for delivery?

A5: The ZY PR Potato Flour Processing Machinery is packaged in a wooden box for delivery.

Q6: What is the delivery time for the ZY PR Potato Flour Processing Machinery?

A6: The delivery time for the ZY PR Potato Flour Processing Machinery is 30-45 days.

Q7: What are the payment terms for the ZY PR Potato Flour Processing Machinery?

A7: The payment terms for the ZY PR Potato Flour Processing Machinery are TT (Telegraphic Transfer).

Q8: What is the supply ability of the ZY PR Potato Flour Processing Machinery?

A8: The supply ability of the ZY PR Potato Flour Processing Machinery is 25 sets per month.

Q9: What is the price for the ZY PR Potato Flour Processing Machinery?

A9: The price for the ZY PR Potato Flour Processing Machinery is negotiable.