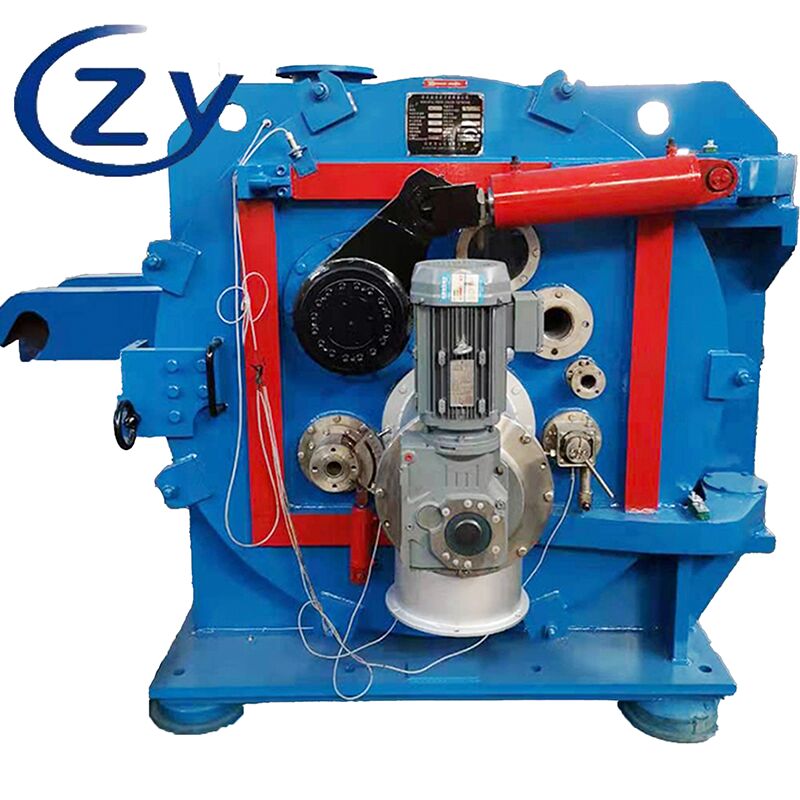

High-Capacity Peeler Centrifuge - Dewatering Equipment for Cassava Flour Slurry in Cassava Flour Processing Facilities

Product Details:

| Place of Origin: | henan china |

| Brand Name: | ZY |

| Model Number: | GK1250 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | 50000 |

| Packaging Details: | wooden box |

| Delivery Time: | 2month |

| Payment Terms: | L/C,T/T |

| Supply Ability: | 5set one month |

|

Detail Information |

|||

| Size: | Customized As Per The Type | Reliability: | High |

|---|---|---|---|

| Product Name: | Scraper Centrifuge | Power: | Electric |

| Vibration Level: | Low | Temperature: | Low |

| Capacity: | High | Noise Level: | Low |

| Maintenance: | Easy | Productname: | Scraper Centrifuge |

| Machinery Function: | Starch Dehydration Equipment | Applicable Industries: | Food & Beverage Factory |

| Raw Material: | Cassava,potato,sweet Potato | ||

| Highlight: | high-capacity peeler centrifuge for cassava flour,dewatering equipment for cassava slurry,decanter scraper centrifuge with warranty |

||

Product Description

High-Capacity Peeler Centrifuge - Dewatering Equipment for Cassava Flour Slurry in Cassava Flour Processing Facilities

Product Description:

The siphon peeler centrifuge is developed based on the standard peeler centrifuge. It uses a siphon to enhance the force that pushes clarified liquid through the filtration medium into the liquid chamber; the liquid is then discharged out of the basket via the siphon tube. Adjusting the siphon tube’s position can alter the liquid level in the suction chamber, thereby regulating filtration force, speed, output, solid cake dryness, and cleaning efficiency.

Features:

- Fully automated operation lowers the intensity of manual labor.

- A fully enclosed structure delivers an optimal operating environment.

- All actuating components rely on hydraulic systems for automatic control, ensuring consistent and dependable operation.

- The electrical system is equipped with PLC control, featuring accurate movements and simple adjustment.

Technical Parameters:

| Parameter | Value |

|---|---|

| Noise Level | Low |

| Power | Electric |

| Size | Customized As Per The Type |

| Reliability | High |

| Maintenance | Easy |

| Temperature | Low |

| Material | Stainless Steel |

| Vibration Level | Low |

| Capacity | High |

| Application | Separation Of Solids From Liquids |

| Automatic Dewatering Machine | Yes |

| Starch Peeler Centrifuge | Yes |

Applications:

Application scope

Widely used in industries such as chemical engineering, grain deep processing, food, pharmaceuticals, and light industry.

Customization:

- Brand Name: ZY

- Model Number: GK

- Place of Origin: Henan, China

- Temperature: Low

- Vibration Level: Low

- Noise Level: Low

- Application: Separation Of Solids From Liquids

- Durability: High

- Special Features: Automatic Dewatering Machine, Peeler Centrifuge

![]()

FAQ:

- Q: What is Decanter Scraper Centrifuge?

- A: The Decanter Scraper Centrifuge is a kind of centrifugal separator produced by ZY with model number GK, which is from Henan, China.

- Q: What are the features of Decanter Scraper Centrifuge?

- A: The Decanter Scraper Centrifuge has high separation efficiency, low energy consumption, and strong production capacity.

- Q: Are the materials of Decanter Scraper Centrifuge safe?

- A: Yes. The Decanter Scraper Centrifuge is made of high-quality stainless steel, which is safe and durable.

- Q: What is the application of Decanter Scraper Centrifuge?

- A: The Decanter Scraper Centrifuge is widely used in the separation and clarification of materials in the chemical, pharmaceutical, food, and other industries.

- Q: What is the warranty period for Decanter Scraper Centrifuge?

- A: The warranty period is one year from the date of shipment.